While there’s a strong focus on the material design of electrical strut systems (rust is everyone’s enemy, after all) and on ease of installation and modification, the geometry of the design is also important. When the strut system is shaped the right way, it can significantly reduce the risk of contamination. By eliminating flat surfaces and crevices, forward-thinking strut designs reduce the potential surfaces where biohazards commonly form, leading to a decrease in costly risks associated with unsanitary support systems, such as product recalls.

Sanitary food and consumer goods production is complicated even before you take into account impacts from infrastructure. That’s why it’s easy to overlook the important role that electrical strut system design plays in ensuring your business maintains strict safety standards and avoids costly issues such as product recalls.

Two Common Design Feature Problems

There are two common design features that create issues for consumable product manufacturers:

- Flat surfaces

- Crevices

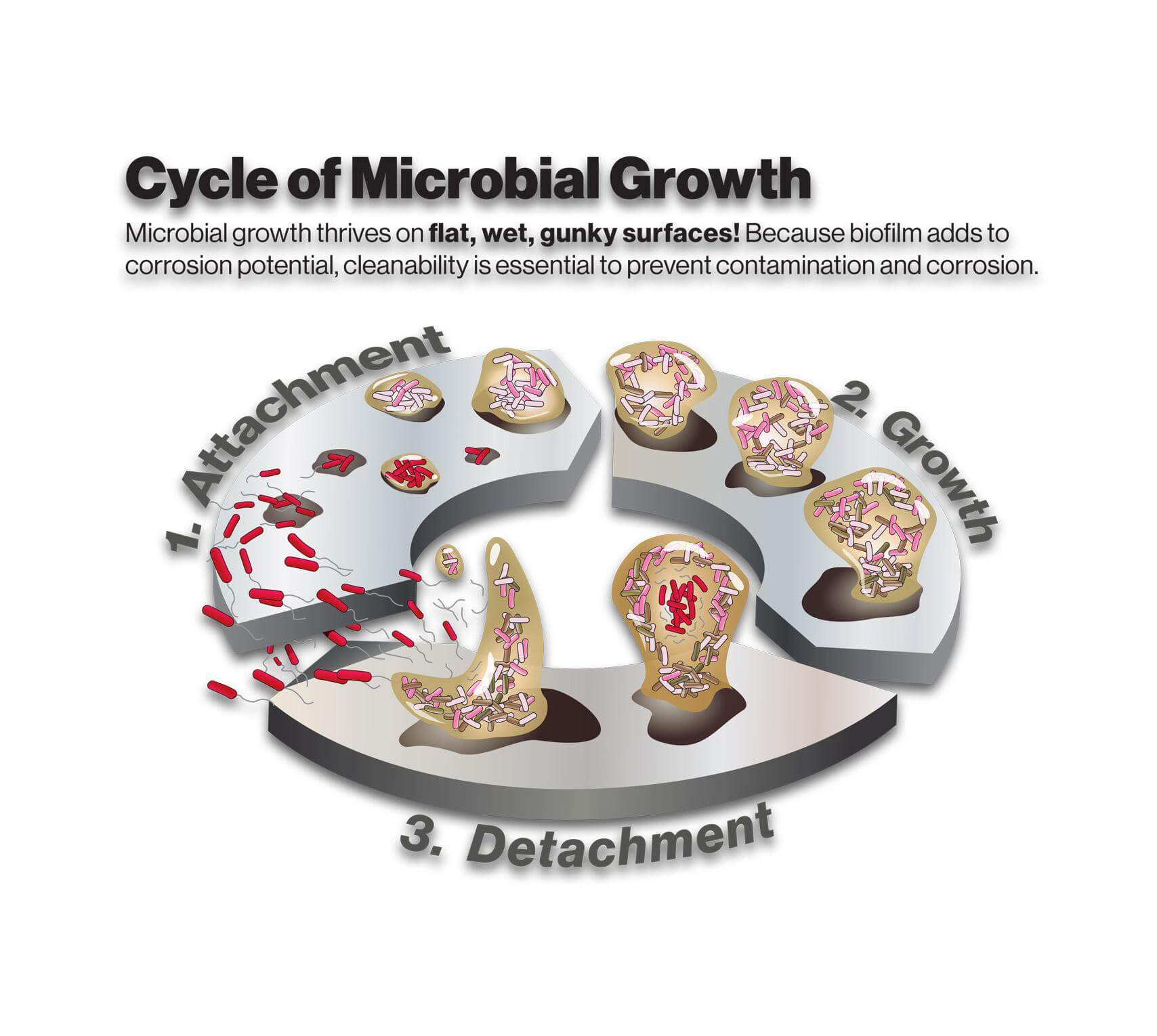

Both of these create a significant potential for unhygienic situations for various reasons. Take flat surfaces, for example. As contaminants build up in these areas, the risk of contamination into the production process increases. Even when the electrical strut system is located away from the food production process, buildup of contaminants on flat surfaces can migrate into the food production process with something as seemingly simple as a gust of wind from an open door or even circulation through HVAC systems.

Also of concern are crevices and other areas hidden from view that are difficult to access and clean. Alongside contaminant build-up, these are locations where insects such as roaches congregate and make nests. Insect contamination is particularly difficult and expensive to root out once they’ve become established.

A 2018 article in Food Processing magazine on pest control also highlights how small changes to infrastructure can make a big difference in contamination risk, especially from insects. “Infrastructure decisions can make it more likely that pests will be drawn to a food facility,” managing editor Kevin T. Higgins explained. -

Additional concern is that flat surfaces make wash down difficult and can also create an area which promotes bacterial growth.

All told, fighting contamination is rarely an issue of making one big change. It involves a holistic approach that takes into account the small areas of your risk profile that can lead to large problems if unaddressed.

Cleanability Is Essential in Strut System Design

Electrical strut systems are essential components in food grade production. As infrastructure, these systems allow manufacturers to have the electrical systems in convenient, safe locations. The introduction of modern strut systems enhanced how easily these systems could be launched and upgraded. However, ease of use was generally preferred, while the consequence of physical design (the geometry of the systems) was generally ignored. How well systems could be fitted together and changed as needed were important, often without consideration to contamination.

The geometry of the design impacts the cleanability factor. The easier your strut system is to clean, and the less likely it is to host contaminants, the less likely it is to be an area of concern or a source of future contamination and recalls.

Focus on using strut systems that are designed to be cleanable at a microbiological level. This means your system should prevent bacterial ingress, discourage survivability of biological contaminants, and reduce their growth and reproduction on both product and non-product contact surfaces.

In all, strut systems designed properly should limit all of the following:

- Crevices and niches (smooth surface and shedding geometry)

- Ingress and growth of microorganisms and infestation of pest

- Product or liquid collection

- Liquid or dust Ingress (hermetically sealed or drainable)

- Build-up of condensation

- Foreign particulate contamination

These are food safety equipment design principles heavily supported by many food processing regulatory and independent bodies, including the North American Meat Institute and the European Hygienic Engineering and Design Group, among others.

Rocket Rack® Utilizes Unique Hygienic Geometric Design

Taking into account the need for electrical strut systems designed with cleanability principles in mind, the Rocket Rack® electrical support system focuses on geometry alongside other features that designed to improve on traditional and other unified strut systems.

By design, Rocket Rack® is a support structure with the requisite geometry to shed liquid and debris from the electrical infrastructure and strut channels. The tented rack, for example, is a hygienic design that features sloped sides at a 45° angle that eliminate the type of bacteria and dirt accumulation common with horizontal edges.

Rounding at the edges of all pieces is also a design feature intentionally designed with cleanability in food safe environments. Not only are posts rounded at the top, but so are the accessories such as cap nuts that go onto the product to secure it. All design features and accessories on Rocket Rack® avoid flat surfaces on a product that’s intended for use in sanitary environments within the product line.

Flat surfaces and crevices promote the build-up of dirt, bacteria, and give space for insect proliferation. It may be difficult to rid your facility of every flat surface or crevice, but Rocket Rack® removes one common area of concern.